Digital flow

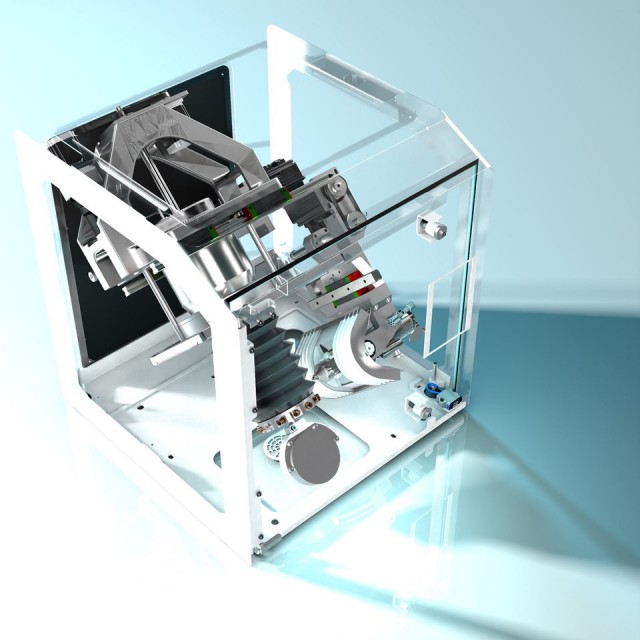

AXYMAT

The first clinic-side milling unit

Dental Machine's AXYMAT milling machine allows all custom-made, office-quality restorations to be machined under lubrication. Dental Machine's approach to design and manufacture is the opposite of the market. Our vision is to produce machines with an industrial logic, solid, stable and durable. This backbone is the signature of Dental Machine, and will be found in every model of our machine tool family. The AXYMAT structure is built on a unique machined frame of great rigidity, which gives precision, stability and durability.

The technical features, over-dimensioned for a cabinet machine, guarantee reliability and resistance:

-

11 instruments with automatic change.

-

5-axis movements for undercut-free machining and highly accurate morphological results.

-

Machine weight of 130 kg which ensures great stability, free of vibration.

-

0,55 kW Jäger spindle, reference partner manufacturer, recognised leader, reliable and durable.

-

Induction motors for smooth movements and jerk-free machined surfaces.

-

Absolute encoders for constant bi-directional information and real-time dynamic correction for perfect angular position.

Production under lubrication:

-

PEEK

-

PMMA

-

Vitroceramics

-

EMAX

-

Feldspathic

-

Premilled

The design and quality components are designed to protect the laboratory's investment, limit breakdowns, achieve competitive processing times, and reduce instrument consumption.

Machining:

-

Crowns

-

Bridges

-

Veneers

-

Inlays

-

Onlays

-

Aligners and trays

-

Surgical Guides (max 5 units)

-

Customized abutments (pre-milled with certified connectors)